I recommend that you use a tenon that is .75” wide x .50” deep and a mortise .75 wide x .625” deep with .75” of material left in your neck block for a bolting ledge. .75 wide is plenty for 1/4-20 threaded inserts.

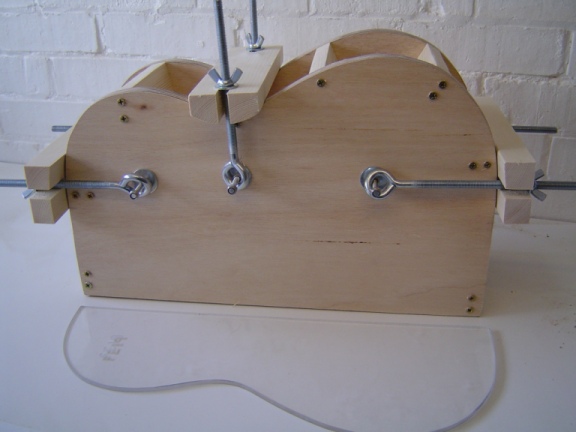

You can build lots of inexpensive variations of bending fixtures. but my guess and recommendations is that you build a Fox style with screw press for waist and cutaway, and that you build from 3/4" ply even if you have to order the ply off the net. The cost to build a Fox style bender form new material is less than $50 including the screw presses and you can build forms for under $10 each. You can start with 3 200W clear light bulbs as your heat source but I do recommend a silicon heating blanket and controler instead. If you use light bulbs I suggest you use a dimer on each bulb for control. This will help you to keep from scorching in the waist and upper bout areas

I know money is a presious comodity but from my experiance with shop made tooling is that this is an area that you either go as cheap as you can and then rebuild better design later and end up spending 1.5 or 2 times as much money as you would have if you went ahead and build the better design in the first place. Same thing can be said about buying your hand tools. But this is a lesson we pretty much all have to learn on our own